StoveTop Coffee Percolator

Areas of Focus: Finite Element Analysis, Manufacturing / Fabrication, Product Design

Project Length: 3 months

Participants: Matthew Derry

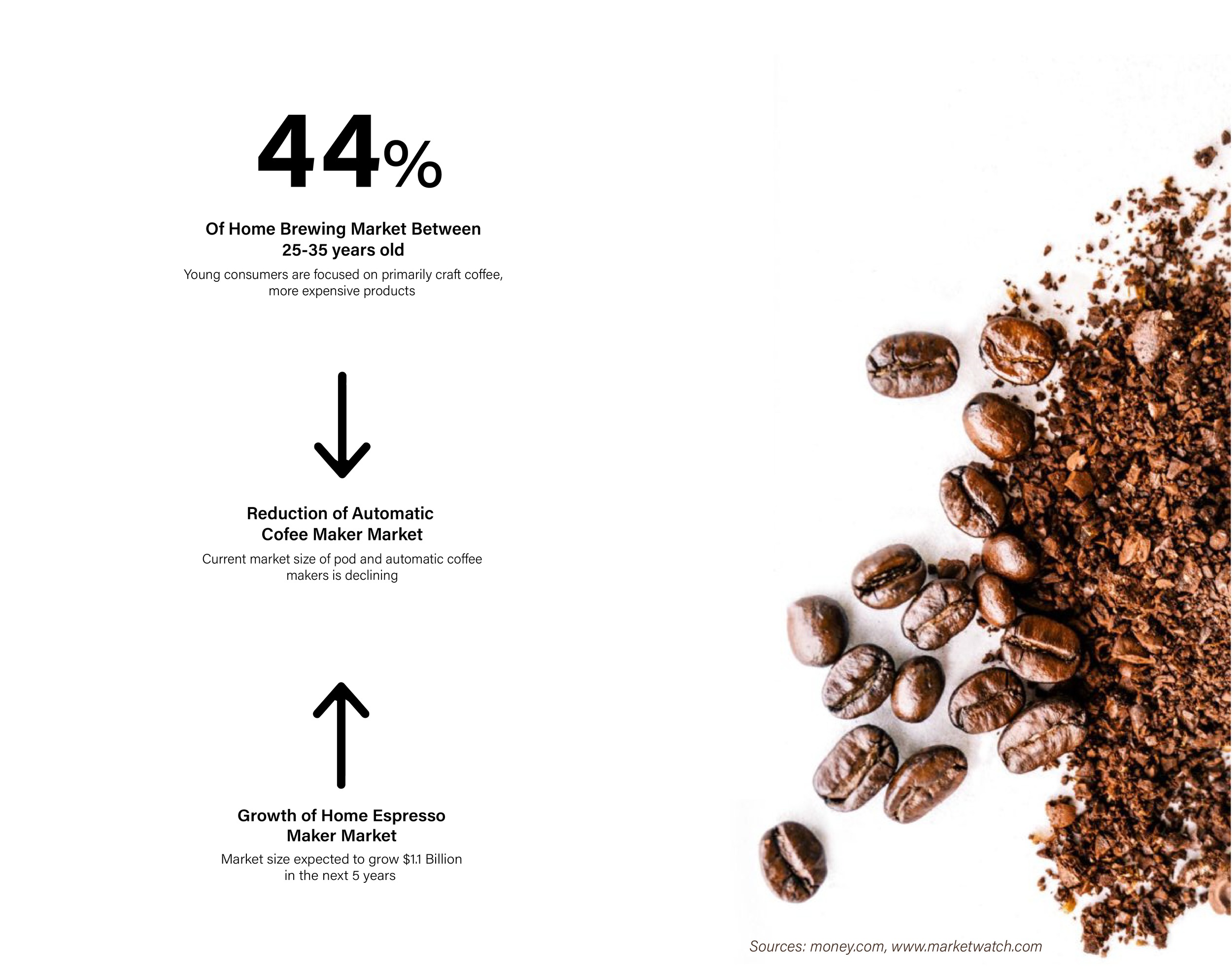

Design Intention

The product aims to produce “moka-pot” style coffee at a higher pressure, producing roughly two shots of espresso. In standard coffee percolators, this process occurs at pressures of 1-2 bar, true espresso is produced at 8-9 bar of pressure. By CNC milling instead of casting these pieces along with reworking the fundamental geometry the design aims to achieve a higher pressure (4-5 bar) and thus, a stronger, richer cup of coffee.

HOW PERCOLATION WORKS

In order to achieve the necessary pressure in the lower reservoir, the product is heated on a stovetop. As the pressure increases the water is forced through the coffee grounds.

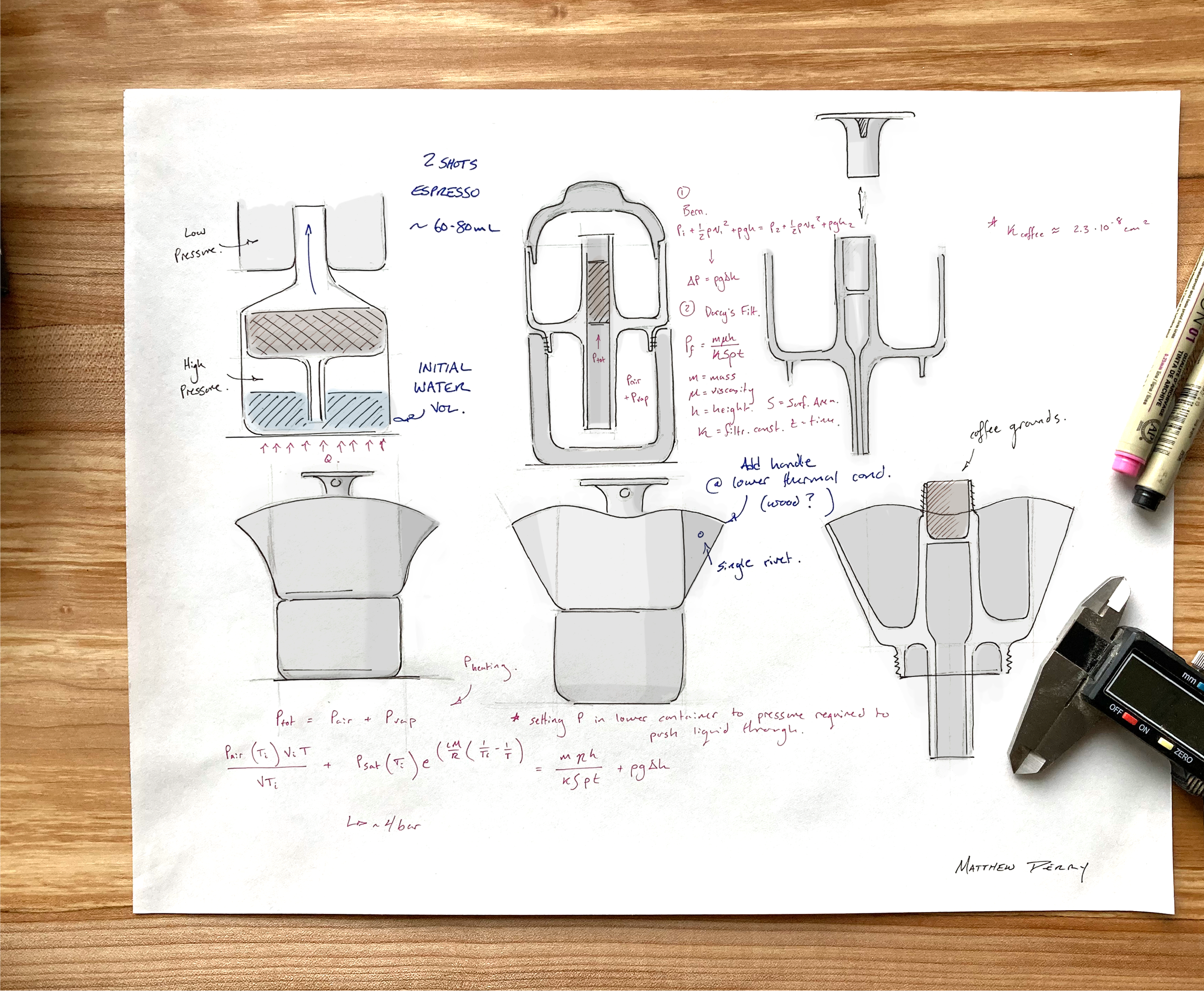

FORM IDEATION

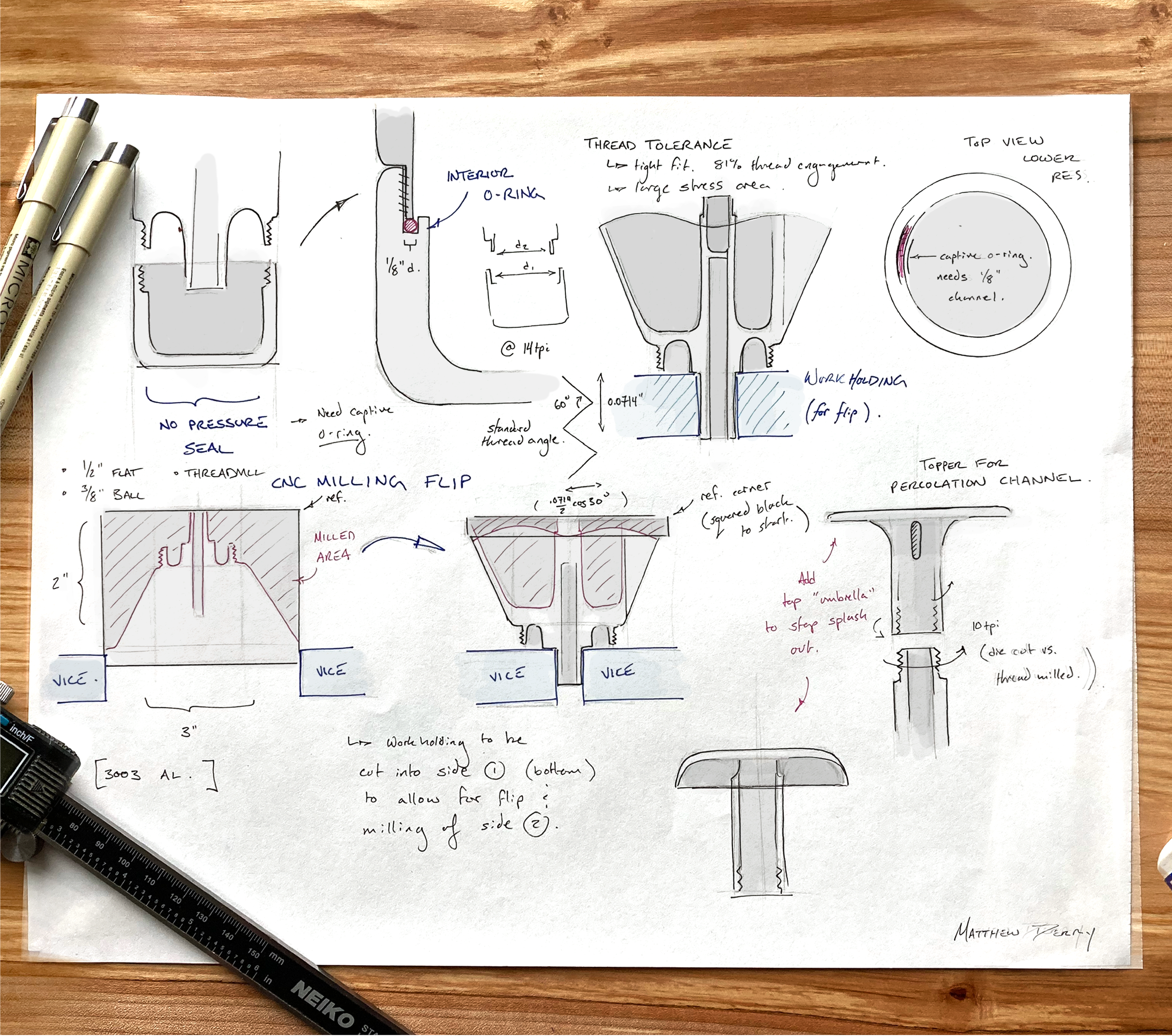

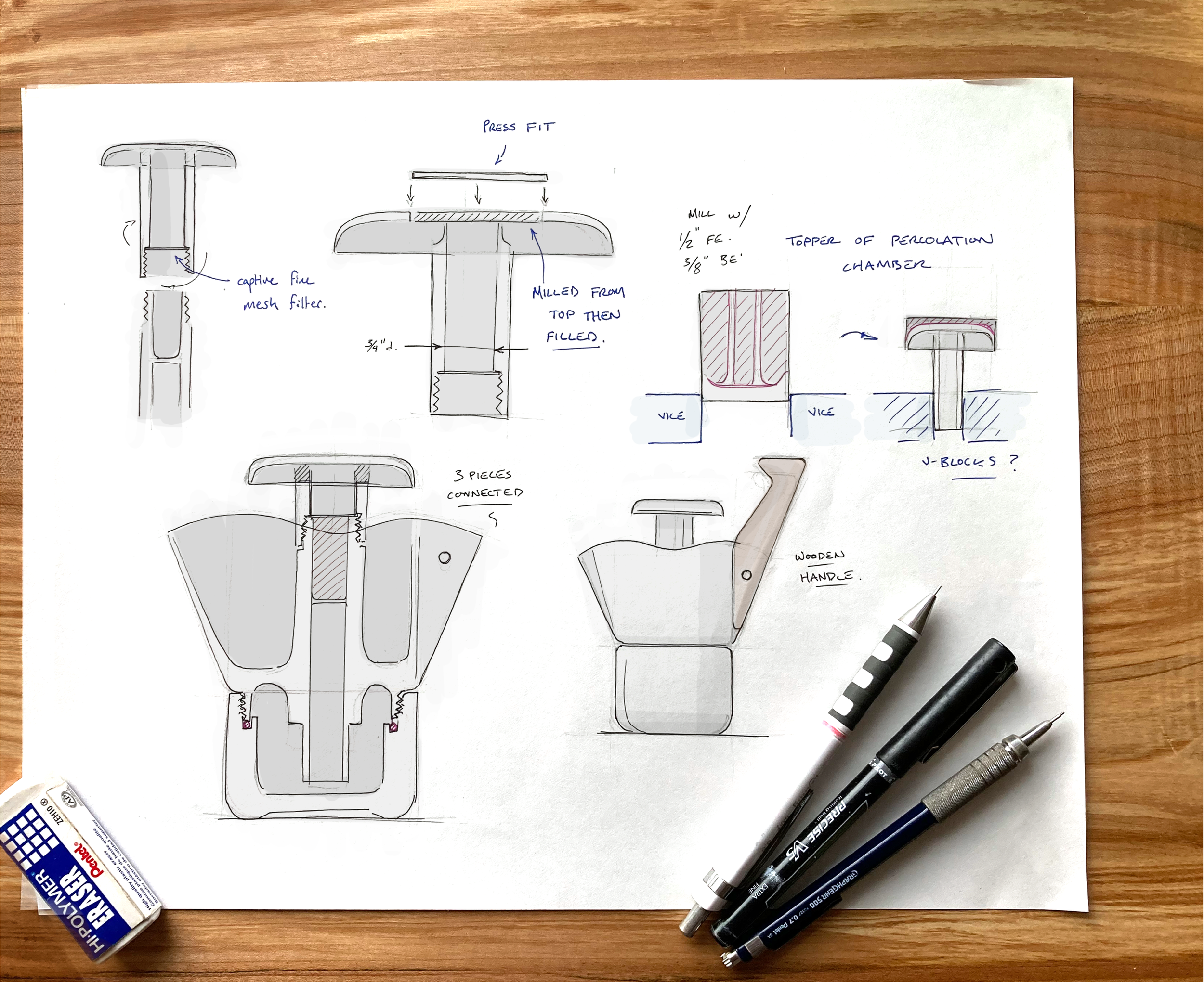

PRODUCTION IDEATION

Continued ideation revolved around solving the technical and manufacturing challenges that this project presented.

FInAL DESIGN

HOW TO USE - STEP BY STEP

FABRICATION - CNC MILLING

The final model was built using Solidworks then the toolpaths were designed using a HSMworks plugin. Everything was machined from a 3” x 5” and a 2” x 2” block of 3003 Aluminum.

DESIGN DETAILS