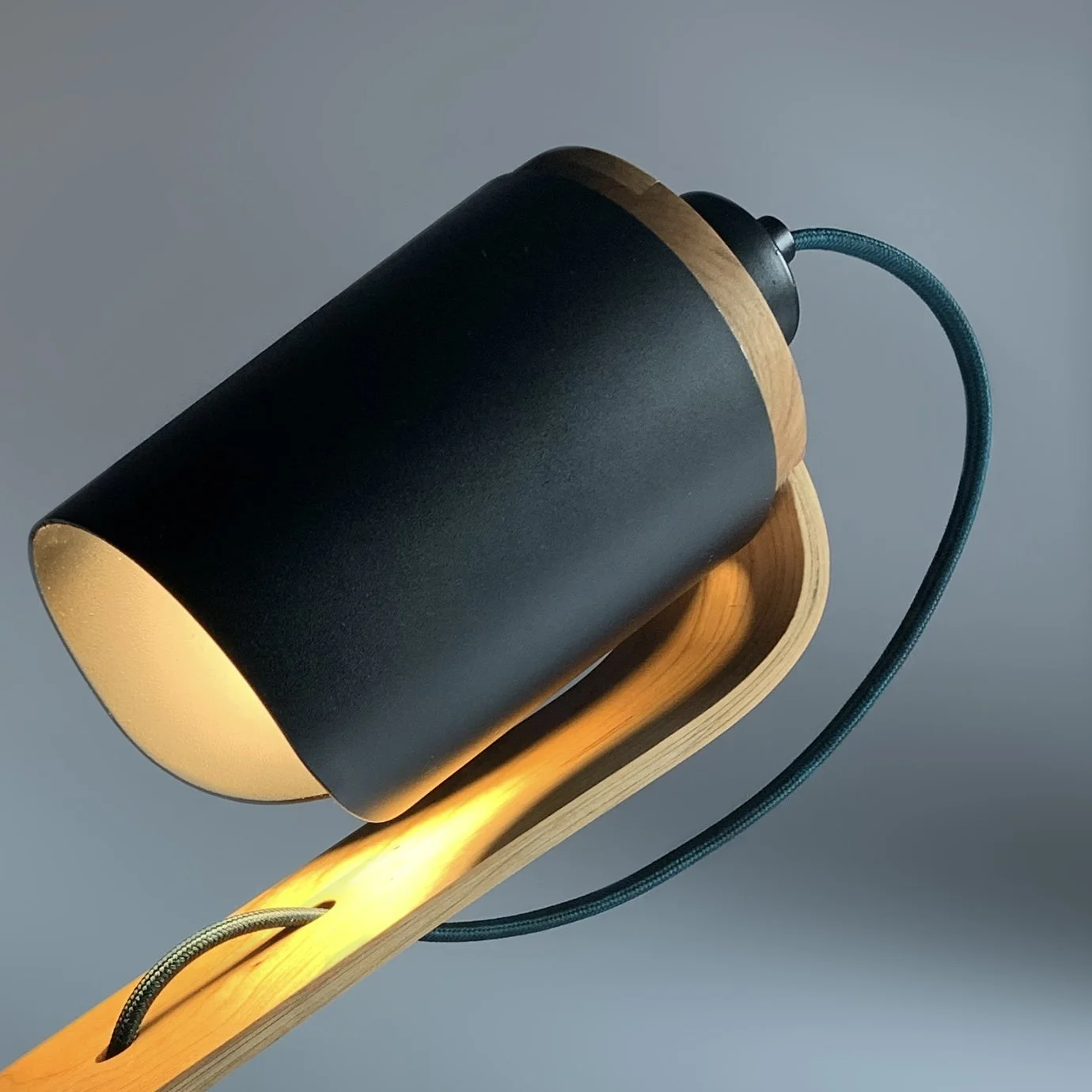

Bent Wood Lamination Bedside Lamp

This design was meant to bring character and evoke joy in what are traditionally mundane and utilitarian objects. The design plays with light and shadow on the wood bent lamination frame. Instead of hiding the cable routing, holes on the wooden frame allow the cord to accentuate the lamps figure. Magnetic attachment of the light shade allows for easy customization and replacement of the bulb.

Construction:

Frame: Bent lamination of cherry and maple

Light Shade: Coated rolled aluminum

Base: Coated rolled aluminum

Light: Dyed braided cable with coated aluminum socket.

Magnetic Shade

Attachment

Three small magnets seat the shade in the correct position and make it easy to remove and switch out depending on the desired use of the lamp.

Product Details - interaction with light

Process Work

See overview of the design and building of the lamp below

1. Wood Preparation

Final design has a cherry exterior with a maple interior, all strips were resawed to width before being steamed to increase their bendability

2. Initial Clamping

Immediately after steaming the strips were clamped in a rough jig of their ultimate shape. This was necessary to ensure that the wood could be bent to the proper form for the final glue-up.

3. Final Clamping Jig

The refined clamping jig is designed for clamping at critical areas during the final glue-up. Key areas such as the two main bends have corresponding supports that hold the wood in the correct position.

4. Final Glue-Up

Glue-up utilizes as many clamps as possible to ensure that the sheets are held tightly together. This was allowed to dry for two days before unclamping.

5. Fixture Point

A disc of cherry was cut to match the curved based, this allows a location for the light fixture to attatch.

6. Shade Design

The main shade is built around a wooden ring with magnets that connect to the wooded base. Sheet Aluminum was rolled to match the correct diameter before the whole piece was sprayed a matte black.

6. Final Assembly

Two holes were drilled in the wooden base to allow a cord to be fed through. A base of aluminum was made to add stability.