OR SCROLL DOWN TO SEE COMBINED FOCUS

StoveTop Coffee Percolator

Areas of Focus: Finite Element Analysis, Manufacturing / Fabrication, Product Design

Project Length: 3 months

Participants: Matthew Derry

Design Intention

The product aims to produce “moka-pot” style coffee at a higher pressure, producing roughly two shots of espresso. In standard coffee percolators, this process occurs at pressures of 1-2 bar, true espresso is produced at 8-9 bar of pressure. By CNC milling instead of casting these pieces along with reworking the fundamental geometry the design aims to achieve a higher pressure (4-5 bar) and thus, a stronger, richer cup of coffee.

HOW PERCOLATION WORKS

In order to achieve the necessary pressure in the lower reservoir, the product is heated on a stovetop. As the pressure increases the water is forced through the coffee grounds.

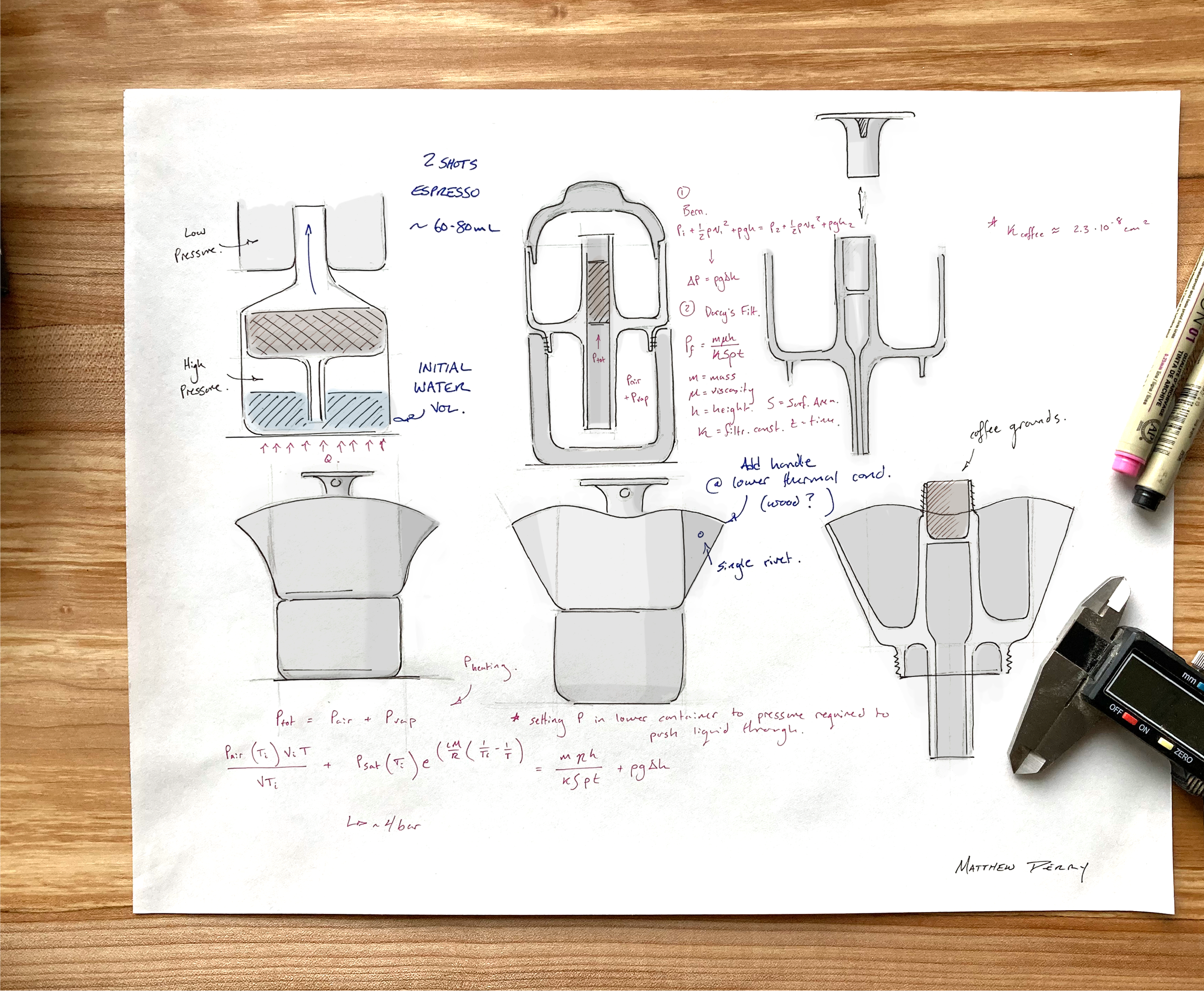

FORM IDEATION

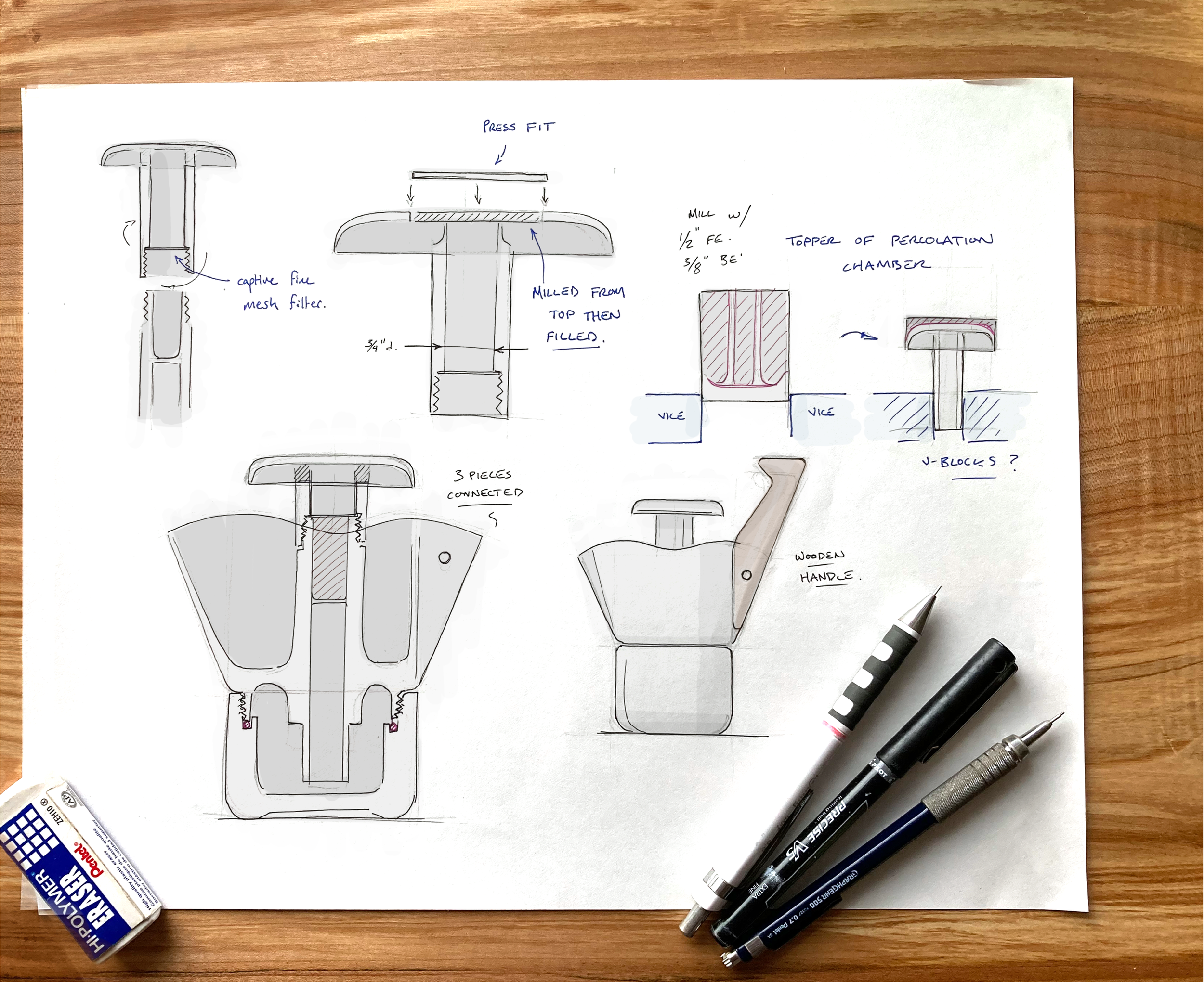

TECHNICAL IDEATION

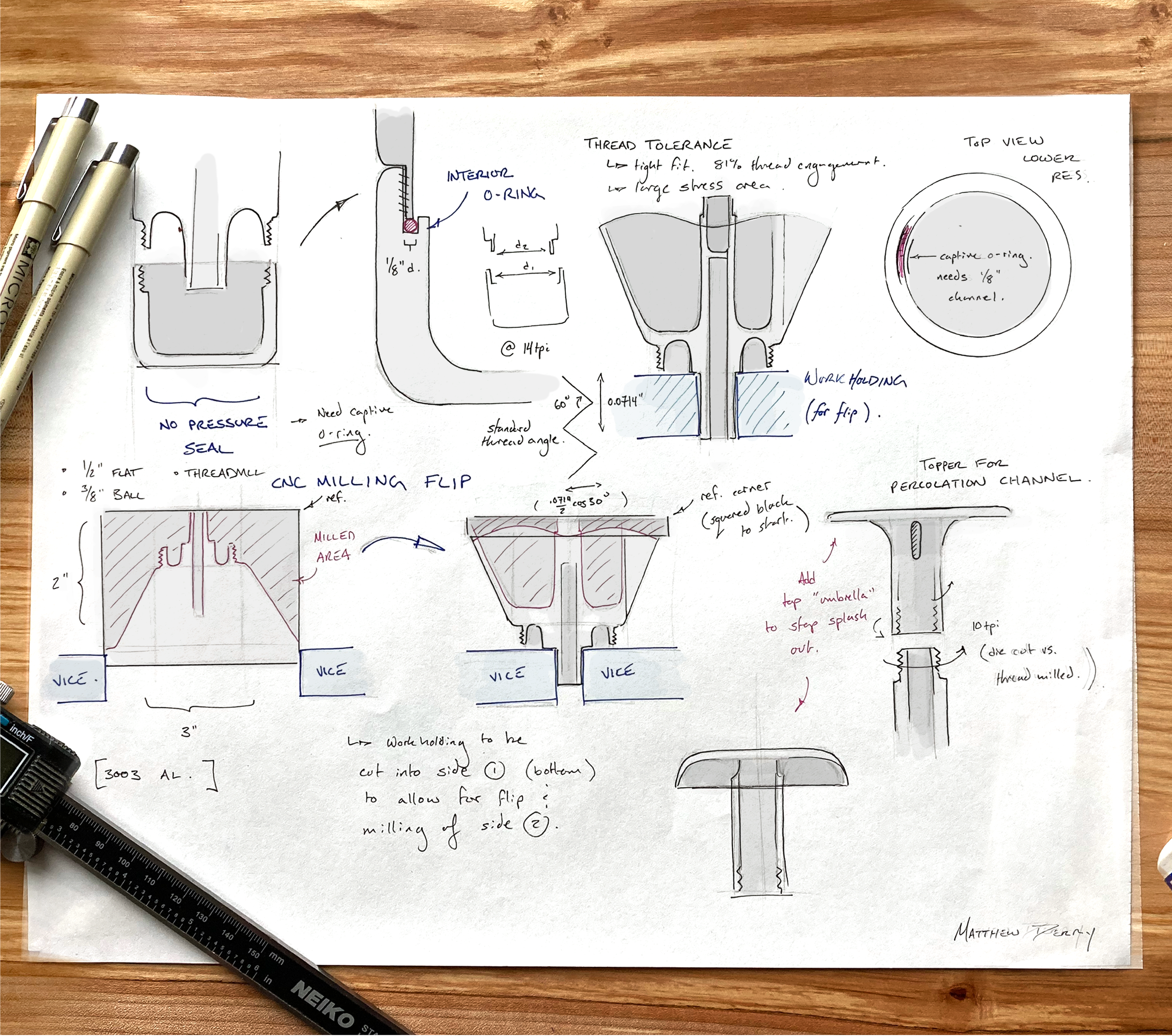

Continued ideation revolved around solving the technical and manufacturing challenges that this project presented.

Theoretical Calculations & Simulations

To match the desired parameters of the design I did pressure calculations for the filtration of the coffee and for the pressure incurred through heating the vessel. This led to design decisions such as the dimensions for the “puck” of coffee grounds as well as the conditions in which the threaded connection and o-ring had to withstand.

See pdf below for the full process of engineering calculations conducted:

TAKEAWAYS:

This analysis resulted in the dimensions of coffee grounds area (height = 1.5”, diameter = 1”) and the theoretical maximum pressure inside the bottom reservoir to be 4.3 bar.

STRESS, STRAIN, & HEAT TRANSFER SIMULATIONS:

With the dimensions set and the maximum internal pressure found, I combined the effects of the thermal load with an internal pressure of 4.3 bar and ran force, stress, and displacement analyses through Solidwork’s simulation software (see images below). This led me to fillet all the corners I could to reduce stress concentrations and ensured that the pressure induced would not lead to failure in any of the components. These simulations assume the o-ring creates a perfect pressure seal and that the threaded connection does not reach failure. Additionally the coffee grounds are taken to be an impermeable layer before the pressure passes 4.3 bar.

Stress due to 4.3 bar pressure

Displacement due to 4.3 bar pressure (visual displacement exaggerated by x 500)

The ideal heat of water for coffee filtration is ~95 degrees Celsius which is achieved within the first 2 minutes of heating on a stovetop surface (determined through Solidworks simulation). Running these analyses helped to define the thickness and geometric form for the bottom of the lower reservoir. Even though it resulted in a less efficient heating method, the final design has a slightly concave bottom so it will sit on surfaces more easily and ensure that small displacements will not effect its stability.

FINAL DESIGN

HOW TO USE - STEP BY STEP

FABRICATION - CNC MILLING

The final model was built using Solidworks then the toolpaths were designed using a HSMworks plugin. Everything was machined from a 3” x 5” and a 2” x 2” block of 3003 Aluminum.

DESIGN DETAILS